Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Here, you can describe a piece of text you want to express

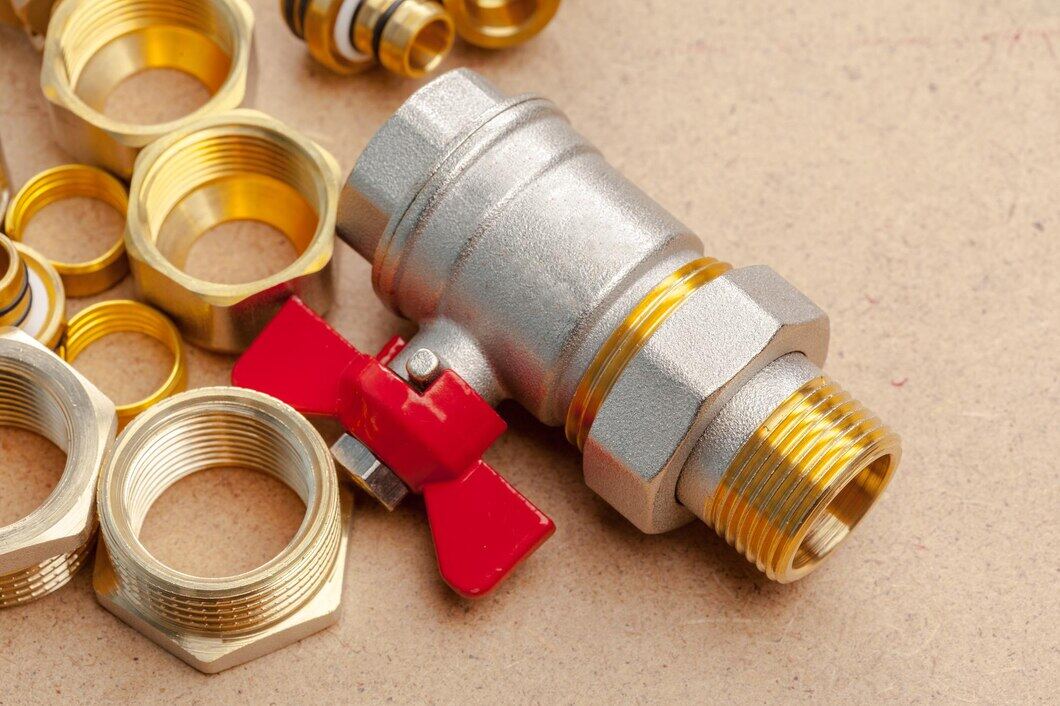

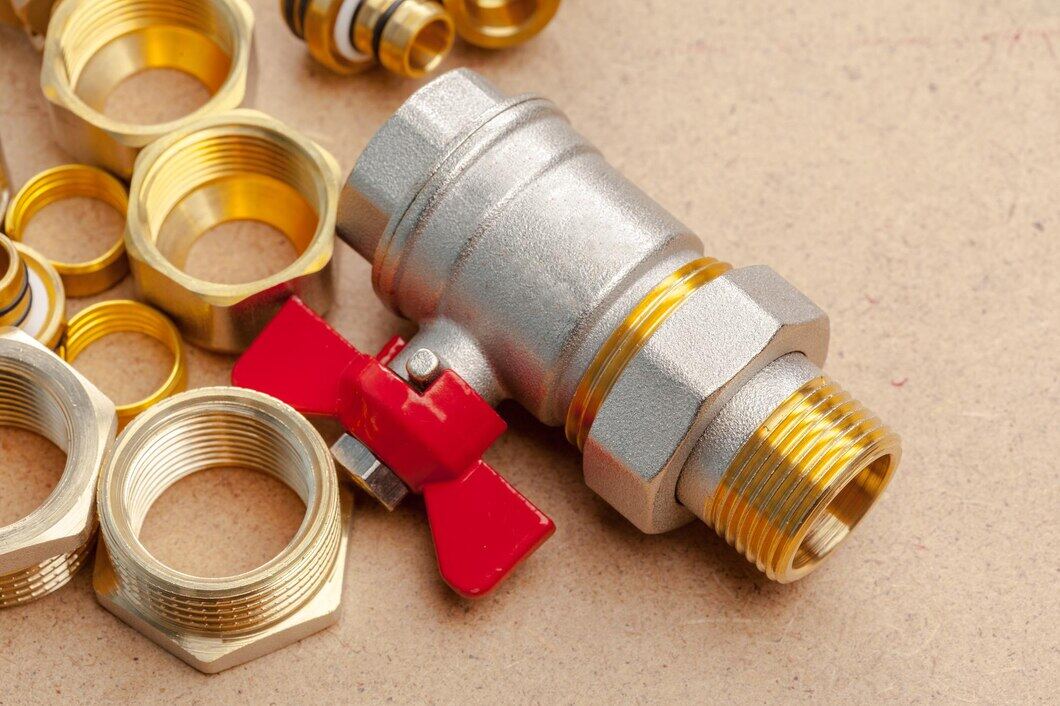

Understanding Cam and Groove Couplings: A Comprehensive Guide

When it comes to connecting hoses and pipes in various industries, cam and groove couplings are an essential component that ensures a secure and efficient connection. This guide will delve into the world of cam and groove couplings, exploring their function, benefits, and applications in a way that is both engaging and informative.

What Are Cam and Groove Couplings?

Cam and groove couplings, also known as cam-lock couplings, are a type of quick-connect coupling used to join hoses and pipes. They consist of a male and female part, which are secured together by a cam lever mechanism. This mechanism allows for a fast, tool-free connection and disconnection, making it highly convenient for users who need to frequently change or disconnect hoses.

The basic design of a cam and groove coupling includes:

- Female Coupler: This part has internal grooves and is designed to fit the male adapter.

- Male Adapter: This part has external cams that fit into the grooves of the female coupler.

- Cam Levers: These levers secure the coupling in place by locking the male and female parts together.

How Do Cam and Groove Couplings Work?

The operation of cam and groove couplings is straightforward. To connect the two parts, you align the male adapter with the female coupler, then press the cam levers down. This action locks the two pieces together, creating a secure seal that prevents leaks and ensures a stable connection.

Disconnection is just as simple: lift the cam levers to release the lock and separate the two parts. This quick-connect feature makes cam and groove couplings ideal for applications where time and efficiency are crucial.

Advantages of Cam and Groove Couplings

Cam and groove couplings offer numerous advantages that make them a popular choice in various industries:

Ease of Use: One of the main benefits is their ease of use. The quick-connect and disconnect feature allows users to change hoses quickly without needing tools, reducing downtime and increasing productivity.

Durability: Cam and groove couplings are made from high-quality materials such as aluminum, stainless steel, and brass, making them durable and resistant to wear and tear. This durability ensures a long service life even in demanding environments.

Leak Prevention: The secure connection created by cam and groove couplings helps prevent leaks. The design ensures a tight seal, which is crucial in applications involving liquids or gases.

Versatility: These couplings are available in various sizes and materials, making them suitable for a wide range of applications. Whether you need to connect hoses for water, chemicals, or air, there’s likely a cam and groove coupling that fits your needs.

Cost-Effective: Given their durability and ease of use, cam and groove couplings are a cost-effective solution. They reduce maintenance costs by preventing leaks and are often less expensive than other types of couplings that require more complex mechanisms or tools.

Applications of Cam and Groove Couplings

Cam and groove couplings are used in a variety of industries and applications. Here are some common examples:

Agriculture: In agriculture, cam and groove couplings are used to connect irrigation systems, spray equipment, and other farming machinery. Their ease of use and secure connection are valuable in the field where quick changes are often necessary.

Construction: Construction sites often use cam and groove couplings to connect hoses for water, air, and other fluids. Their durability makes them ideal for the rugged conditions typically found on construction sites.

Chemical Processing: The chemical industry requires couplings that can handle corrosive substances. Cam and groove couplings made from materials resistant to chemicals, like stainless steel or polypropylene, are used to connect hoses and pipelines in this sector.

Oil and Gas: In the oil and gas industry, cam and groove couplings are employed for connecting hoses in the transfer of petroleum products. Their robust construction ensures they can withstand the high pressures and harsh conditions of this industry.

Food and Beverage: For the food and beverage industry, hygiene is a top priority. Cam and groove couplings made from food-grade materials are used to connect hoses in processing and distribution systems, ensuring that the products remain uncontaminated.

Choosing the Right Cam and Groove Coupling

Selecting the appropriate cam and groove coupling involves considering several factors:

Material: The material of the coupling should be compatible with the substances it will be handling. Common materials include aluminum, stainless steel, brass, and various polymers.

Size: Ensure that the coupling is the right size for the hoses or pipes you are connecting. Proper sizing is crucial for a secure fit and to prevent leaks.

Pressure Rating: Different couplings have different pressure ratings. Make sure to choose a coupling that can handle the pressure requirements of your application.

Temperature Resistance: If your application involves high or low temperatures, select a coupling that can withstand the temperature extremes.

Regulations: In some industries, there may be specific regulations or standards that couplings need to meet. Verify that the cam and groove coupling you choose complies with any relevant industry standards.

Maintenance and Care

Proper maintenance of cam and groove couplings can extend their lifespan and ensure reliable performance. Here are some tips for maintaining these couplings:

Regular Inspection: Check couplings regularly for signs of wear, damage, or corrosion. Early detection of issues can prevent more serious problems.

Cleaning: Keep the couplings clean to prevent build-up of debris or contaminants. Use appropriate cleaning methods based on the materials and substances involved.

Lubrication: Some cam and groove couplings may benefit from periodic lubrication to ensure smooth operation of the cam levers.

Replacement: Replace any damaged or worn couplings promptly to maintain safety and efficiency.

Future of Cam and Groove Couplings

As technology advances, we can expect further innovations in cam and groove couplings. Developments might include new materials that offer better performance or couplings with enhanced features for specific applications. Staying updated with industry trends and advancements will help ensure that you are using the most effective solutions for your needs.

Conclusion

Cam and groove couplings are a vital component in a wide range of industries, providing a simple, reliable, and efficient way to connect hoses and pipes. Their ease of use, durability, and versatility make them a popular choice for many applications. By understanding their operation, advantages, and applications, you can make informed decisions about the best coupling solutions for your needs.

Whether you’re in agriculture, construction, chemical processing, oil and gas, or food and beverage, cam and groove couplings offer a dependable connection that can enhance your operations. Embracing the benefits of these couplings and maintaining them properly ensures that they continue to perform effectively, contributing to the success of your projects and processes.