Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Air Hose Coupling Universal Hose End

The hose end is a Universal Hose End for Air Hose Coupling, which comes in carbon steel. The most common hose ends are made of carbon steel because they are affordable and long-lasting.

Product parameters:

| Product Name | Air hose coupling(U.S Type) |

|---|---|

| Size | 1/4'' - 2'' |

| Type | Hose End ; Male End; Female End |

| Material | Carbon Steel |

| Standard of material | Our camlock coupling are made to standard of A - A-59326(previously called MIL-C-27487)or DIN 2828. |

| Technology | Precision Manufacturing |

| Surface Treatment | Zinc Plating |

| Accessories | We equipped with Rings, Pins and Safety clips |

| Material of Handle | Aluminium handles; Stainless steel handles; Brass handles |

| Pressure | 1/2'' -2'' 250psi |

| Thread Type | NPT |

| Connection method | Thread Connecting |

| Gasket | NBR, EPDM, Viton, PTFE gasket are all available. If you have any special requests of material, just feel free to contact us. |

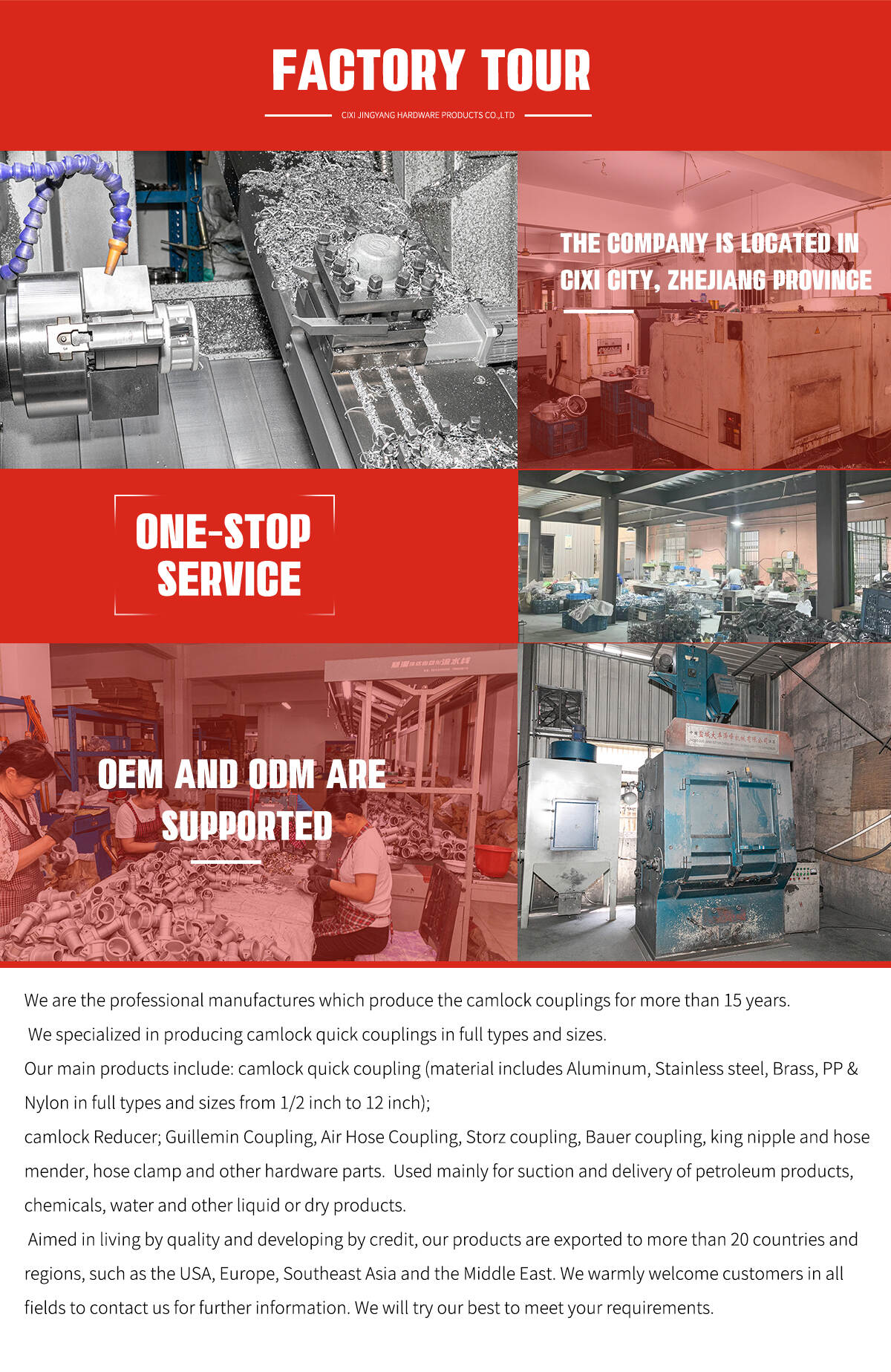

| Our advantages | 1. We are professional manufactures of producing camlock couplings for more than 15 years.2. We have factory, we will provide thebest price.3. Our products are of high quality and each product is thorugh strict inspection.4. We make sure delivery is on time and won't delay the delivery. |

| Application | Pipe Lines Connect;Industry; Oil; Gas |

| port | Ningbo |

| MOQ | 200pcs |

Product Description

The hose end is one of the Air Hose Coupling Universal Hose End, which is available for carbon steel. The carbon steel hose ends are the most popular because of their economical and durable life.

Hose ends are available in 1/4" to 2" with matched 2-lug or 4 lugs.

WHAT ARE THE DIFFERENT TYPES OF AIR HOSE COUPLINGS?

Most applications, such as air hose assemblies and air compressors will use or require a national pipe thread or quick disconnect connection. With quick disconnects, you’ll usually encounter a plug (which serves as a male end) and a coupler (serving as the female end). Don’t be surprised if you see both types of connections used in the same assembly. Many times, our hose assemblies will be built with NPT end connections in order to attach the quick disconnects.

In ninety-nine percent of all applications, the quick disconnects used are industrial, automotive, and ARO.

CAN YOU USE AIR HOSE COUPLINGS FOR WATER?

No. You should not use any air-specific item for a water application. Doing so can significantly damage your equipment due to residual water. Any pneumatic quick disconnect is not going to be recommended to, or rated for, use on a water application.

HOW TO STOP AIR HOSE COUPLINGS FROM LEAKING?

Our first step in stopping an air hose fitting from leaking is to find and identify the leak point. If the application is leaking from the threads, you can always try Teflon tape, pipe dope, or thread sealant, and then torque your thread down tighter. If you’re leaking from the quick disconnect, it is normally easier and more cost-effective to just purchase a new one, compared to repairing your current quick disconnect.

AIR HOSE COUPLING SAFETY

When working with air hose fittings and compressed air systems, it is deemed safe and effective up to the working pressure of the assembly. It may seem obvious, but maintaining and checking your systems before and after use can help avoid unnecessary mistakes. Remember to check your connections and for cuts or holes in hoses before the operation, and make sure to not leave loose hoses lying around after use.